Here are the pictures. Note that I will have pics with measured drawings a little later.

Click the pic for a larger view and many more details.

|

|

|

Here are the Templates and frame.

|

|

|

Here is a closeup of one template.

|

|

|

Here are the cut and routed plastic pieces.

|

|

|

This is a closeup of the front with the mounting blocks slid into dovetail slots.

|

|

|

This is the front of the (dry fit) assembled case.

|

|

|

This is the view of the (dry fit) assembled back.

|

|

|

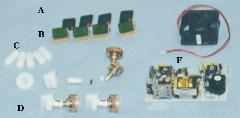

This is a shot of the controls, displays, the power supply, and fan.

|