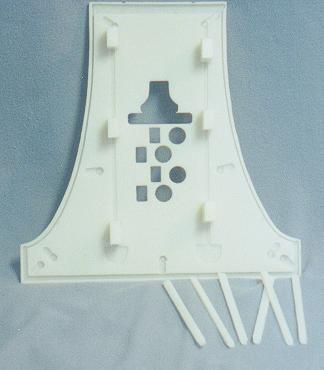

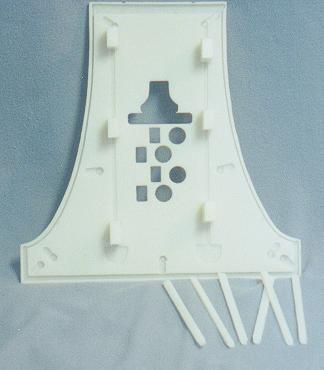

This is a closeup of the front with the mounting blocks slid into dovetail slots Brackets will be attached to them, then the circuit boards can be attached to the brackets. One of the things I found is that while the plastic can be heated and bent around a curve, it really doesn't want to. It wants to warp. So I had to come up with another method. The first one I chose was to cut 1/2" stips of the 1/4" side plastic, trim the ends, roundover one long edge and groove the other. This would allow them to turn in each other, keeping gaps to a minimum. This worked well, but I found that I needed to do this to most of the side. So the next step is to cut down more of the sides to make strips that are 1" to 3" to fit the rest of the curves. I can then run clear tape on the inside to seal them. I actually like this. It adds some texture to the sides.